Cum paharele cu vid revoluționează eficiența procesării cărnii

2026-02-03Știința marinării în vid Paharele cu vid sunt echipamente esențiale în ind...

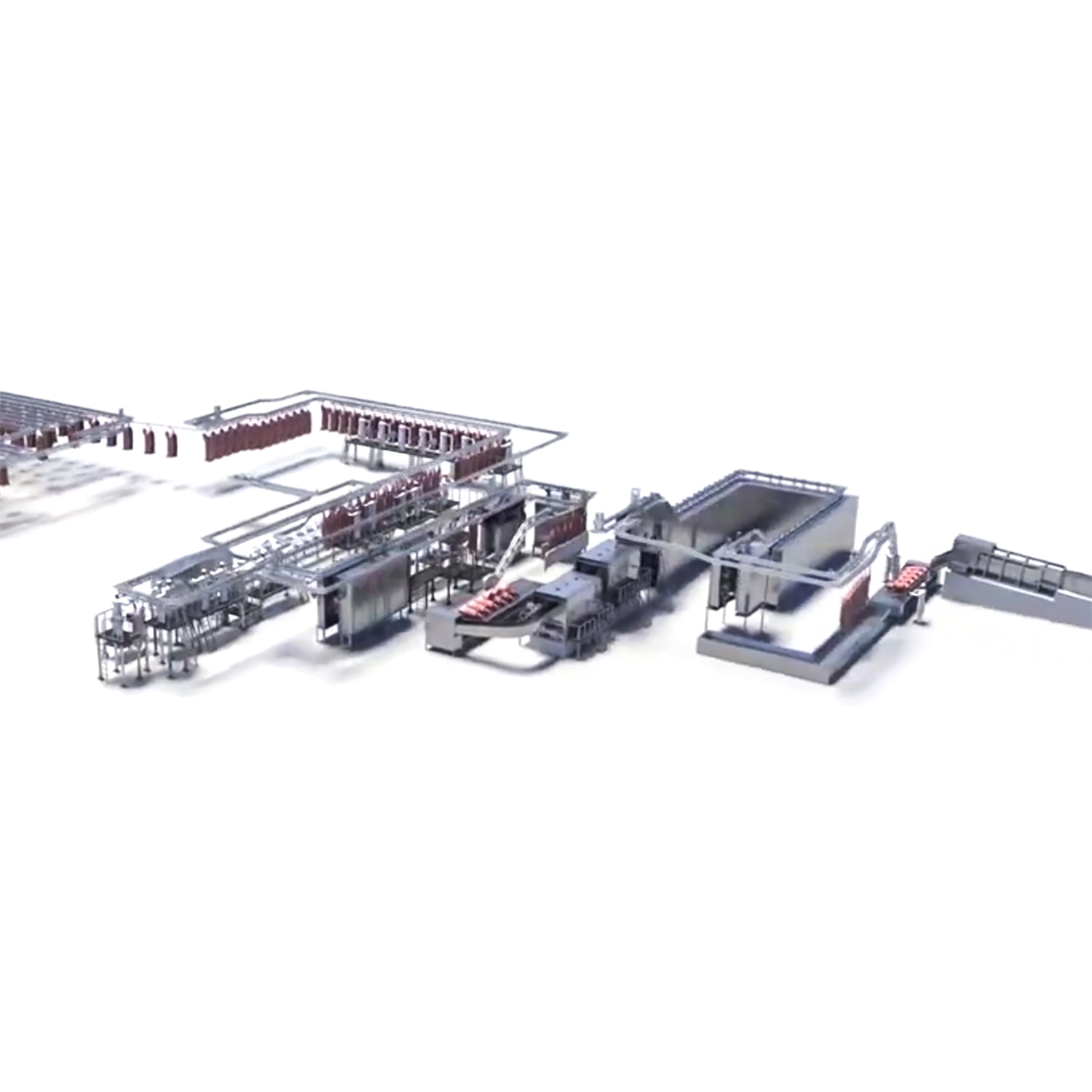

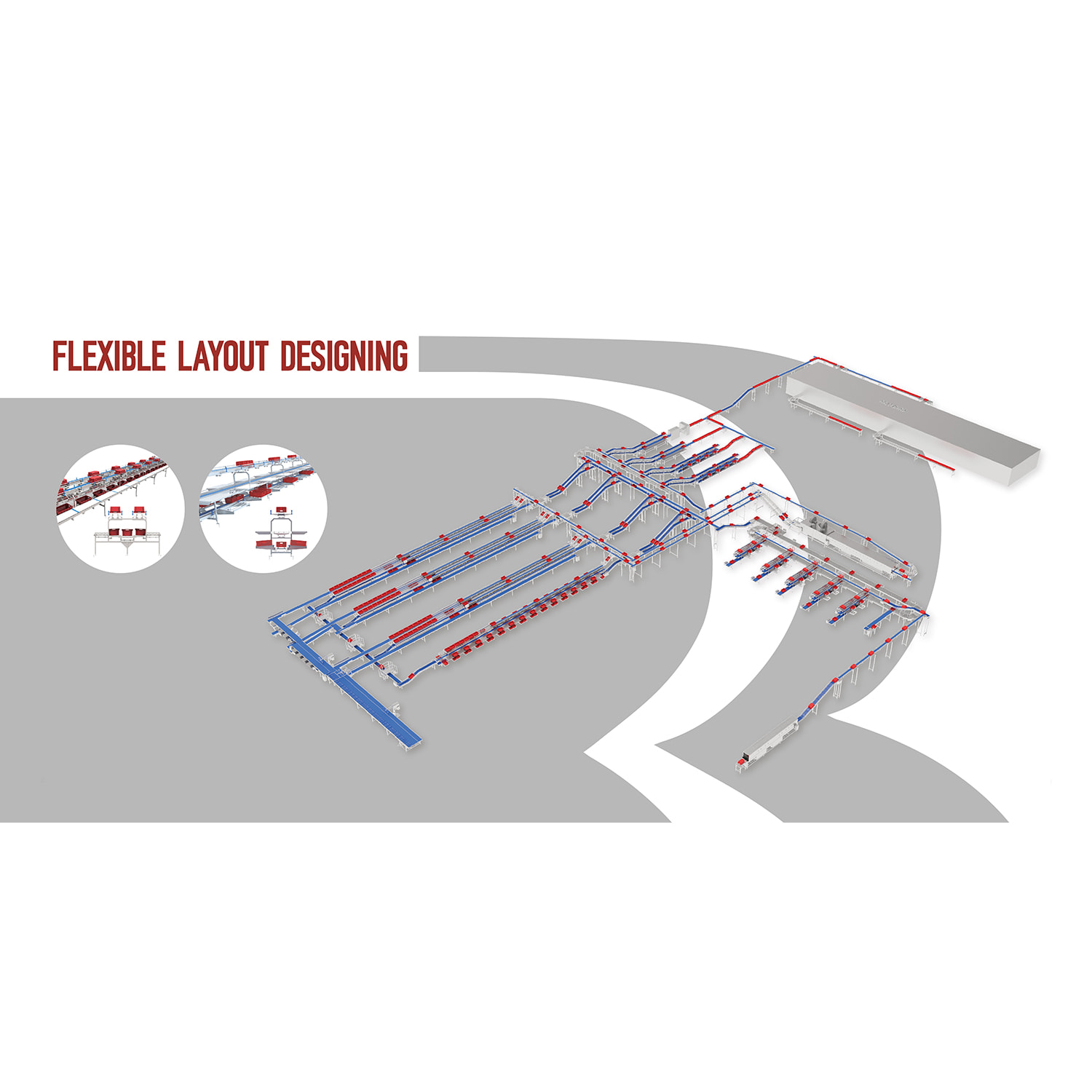

Citeşte mai multCapabil să furnizeze proiecte de propuneri cu desen, fabricare, instalare și punere în funcțiune, adică proiectul Turnkey.

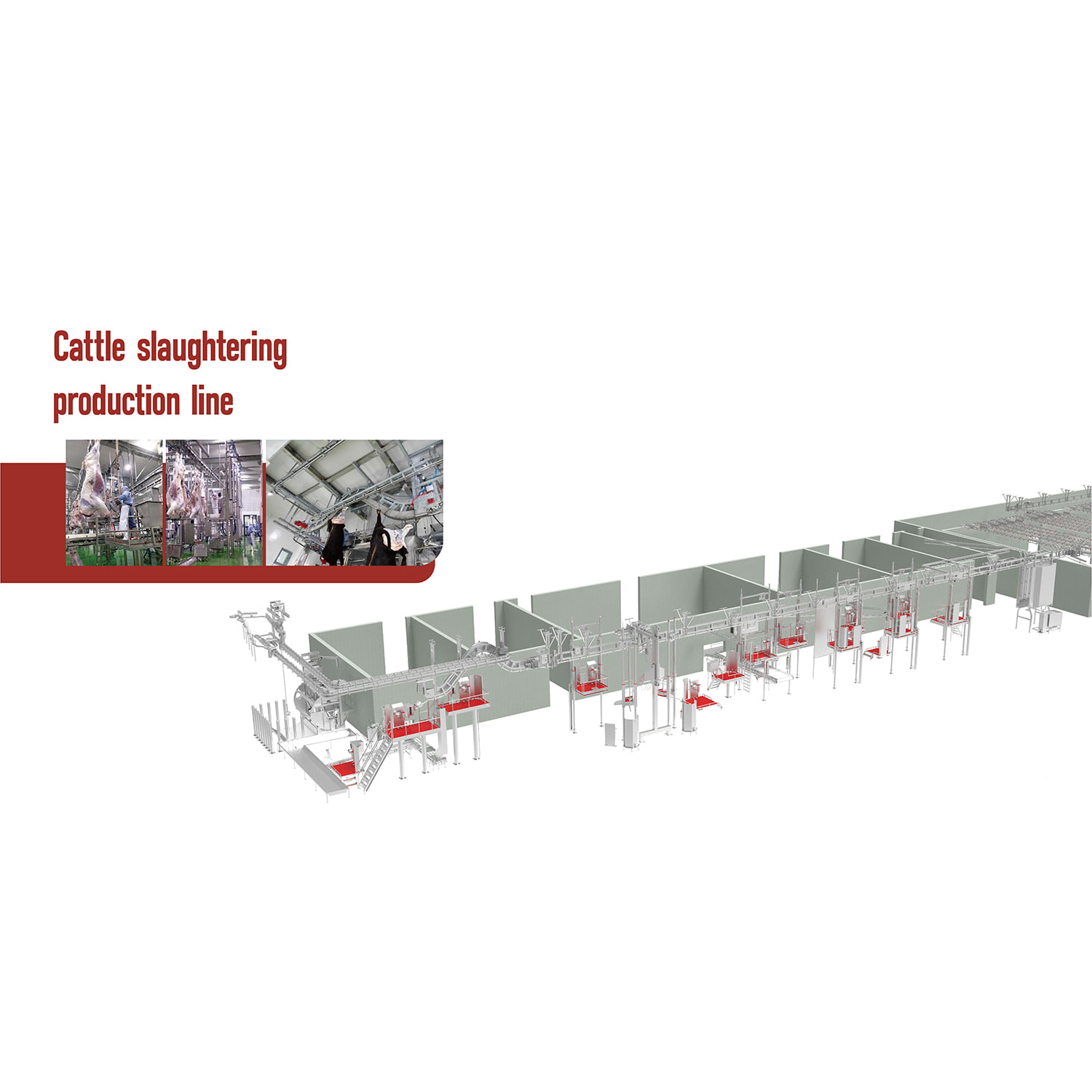

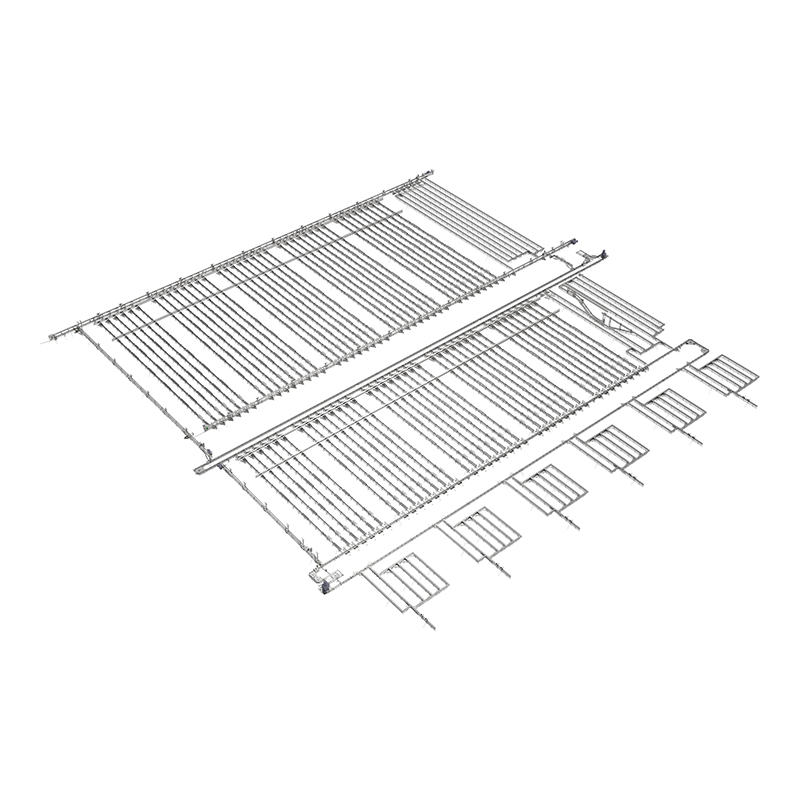

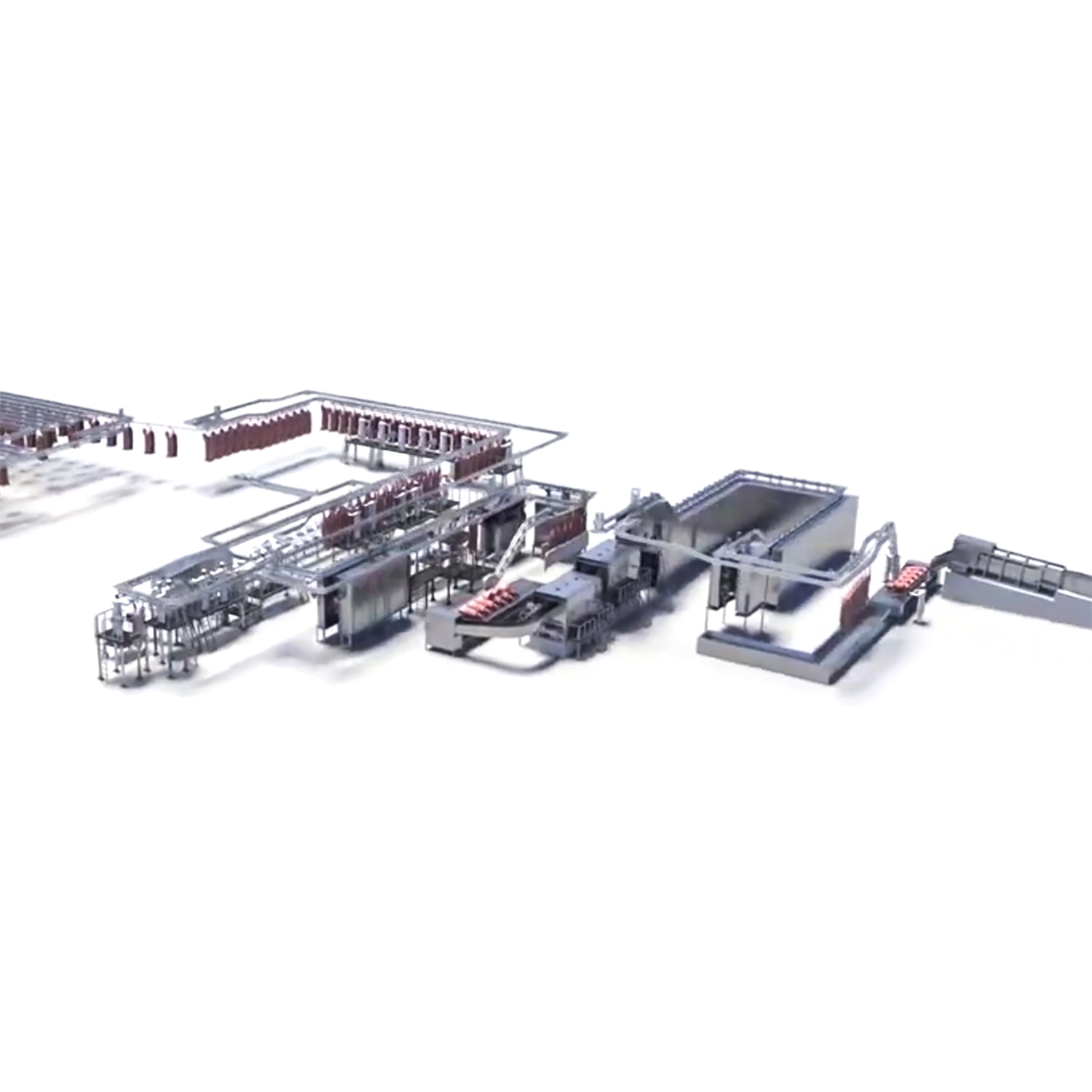

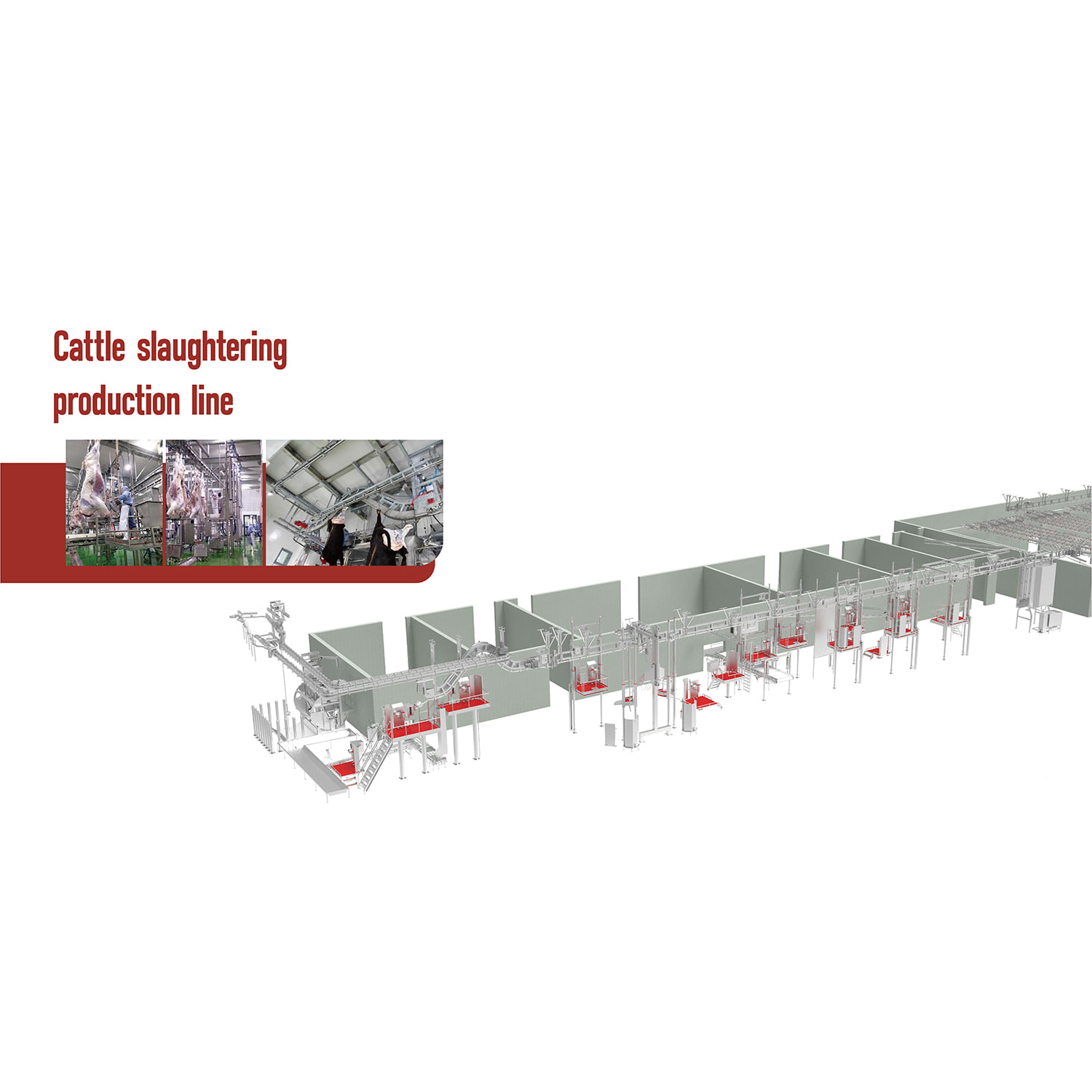

Zhejiang Ribon Intelligent Equipment Co., Ltd. a fost cea mai importantă companie din industria de mașini de prelucrare a cărnii din China, specializată în fabricarea de linii de sacrificare a bovinelor, tăierea și liniile de debutare a bovinelor și porcilor. Capacitatea de producție anuală este 50 pc de linii de producție .

În prezent, lucrăm cu peste 4000 de clienți la nivel global. Viteza de răspuns super-rapid a îmbunătățit o mulțime de servicii noastre, integrată cu calitatea mașinii noastre, aceste două sunt cele mai favorabile avantaje dintre noi.

Atelier de fabricație modernizat, flux de producție avansat, sistem de management complet, vă îmbrățișăm mereu vizita! Suntem întotdeauna cu mintea deschisă și ne așteptăm la alte provocări.

Producători de echipamente de sacrificare a cărnii şi Fabrica personalizată de mașini de debutare a cărnii din China . Sperăm să fim partenerul tău strategic și să ne dezvoltăm împreună!

Știința marinării în vid Paharele cu vid sunt echipamente esențiale în ind...

Citeşte mai mult

Construirea sau modernizarea a Echipament pentru fumători necesită mai...

Citeşte mai mult

Funcțiile de bază ale mașinilor de prelucrare a cărnii în fabricile moderne ...

Citeşte mai mult

Rolul preciziei în lanțurile moderne de aprovizionare cu alimente Modern ...

Citeşte mai mult

Înțelegerea științei tumbării în vid A marinator cu pahare cu vid f...

Citeşte mai mult

Tehnologii avansate de asomare și reținere Fundamentul oricărui modern ...

Citeşte mai mult